What Does Roar Solutions Do?

What Does Roar Solutions Do?

Blog Article

The 2-Minute Rule for Roar Solutions

Table of ContentsIndicators on Roar Solutions You Should KnowGetting The Roar Solutions To WorkThe Basic Principles Of Roar Solutions Roar Solutions Fundamentals Explained

The tools register is an extensive data source of tools records that consists of a minimum set of fields to identify each thing's place, technological specifications, Ex classification, age, and ecological information. This information is critical for tracking and handling the equipment efficiently within unsafe locations. In contrast, for periodic or RBI tasting evaluations, the quality will certainly be a combination of In-depth and Close examinations. The ratio of Detailed to Shut inspections will be established by the Devices Risk, which is examined based upon ignition danger (the likelihood of a resource of ignition versus the likelihood of a flammable atmosphere )and the hazardous location classification( Area 0, 1, or 2). This variant will certainly also influence the resourcing requirements for job prep work. When Whole lots are defined, you can create tasting plans based upon the sample dimension of each Whole lot, which refers to the number of arbitrary devices products to be checked. To determine the called for example dimension, 2 aspects need to be assessed: the size of the Great deal and the classification of examination, which shows the level of effort that need to be applied( reduced, normal, or boosted )to the examination of the Whole lot. By incorporating the category of examination with the Lot size, you can then develop the ideal denial criteria for a sample, indicating the permitted variety of malfunctioning things located within that example. For even more details on this process, please describe the Energy Institute Standards. The IEC 60079 typical suggests that the optimum period between examinations need to not go beyond 3 years. EEHA examinations will certainly likewise be carried out outside of RBI campaigns as component of scheduled maintenance and tools overhauls or fixings. These examinations can be attributed towards the RBI sample dimensions within the influenced Whole lots. EEHA assessments are carried out to identify mistakes in electric equipment. A weighted racking up system is necessary, as a solitary piece of equipment might have several faults, each with differing degrees of ignition risk. If the combined rating of both assessments is less than twice the mistake rating, the Lot is deemed appropriate. If the Great deal is still thought about inappropriate, it should undergo a full inspection or validation, which might cause more stringent evaluation protocols. Accepted Whole lot: The reasons for any kind of faults are recognized. If a typical failing mode is located, extra tools may require maintenance. Mistakes are classified by seriousness( Safety and security, Stability, Housekeeping ), making sure that urgent problems are analyzed and dealt with without delay to reduce any kind of effect on safety or procedures. The EEHA data source should track and tape the lifecycle of faults together with the rehabilitative actions taken. Carrying out a durable Risk-Based Inspection( RBI )technique is crucial for making sure conformity and safety and security in managing Electrical Devices in Hazardous Locations( EEHA). Automated Fault Scoring and Lifecycle Administration: Easily manage mistakes and track their lifecycle to enhance inspection precision. The intro of this support for risk-based assessment better strengthens Inspectivity's setting as a best-in-class option for regulatory compliance, in addition to for any kind of asset-centric inspection use case. If you have an interest in discovering extra, we welcome you to ask for a demo and uncover just how our remedy can change your EEHA monitoring procedures.

With over one decade of mixed Ex lover experience (IECEx/ATEX, EEHA), Saipex started to advertise the significance of competence eeha courses of all employees associated with the Hazardous Area area in 2019. In 2021, our partnership with IndEx and Technology Ability International (TSI) noted a milestone in the Saipex roadway to continue Ex-spouse enhancement.

The Best Strategy To Use For Roar Solutions

In terms of eruptive threat, a harmful location is an environment in which an explosive ambience exists (or might be anticipated to be present) in quantities that need unique safety measures for the building and construction, installation and use of devices. In this write-up we explore the difficulties encountered in the workplace, the threat control actions, and the needed expertises to work safely.

(https://sitereport.netcraft.com/?url=https://training.roarsolution.com.au)

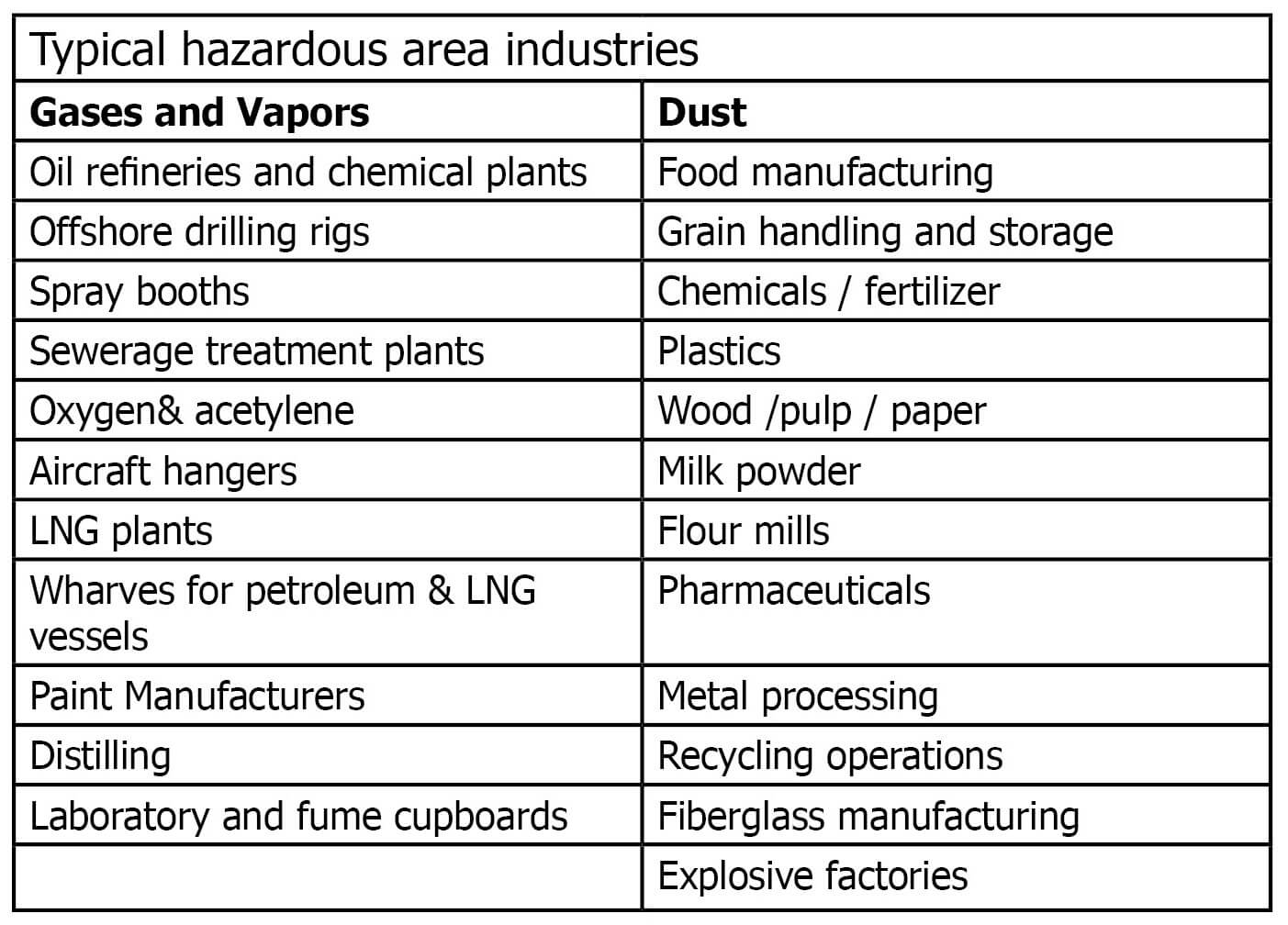

It is an effect of contemporary life that we produce, store or manage an array of gases or liquids that are regarded flammable, and a variety of dirts that are deemed combustible. high voltage courses. These compounds can, in particular problems, form explosive environments and these can have major and tragic repercussions. A lot of us recognize with the fire triangular get rid of any one of the 3 components and the fire can not occur, but what does this mean in the context of harmful locations? When damaging this down right into its simplest terms it is essentially: a combination of a specific quantity of launch or leakage of a certain substance or material, blending with ambient oxygen, and the visibility of a source of ignition.

This is after that verified through inspection and screening and is preserved throughout the life of the installation by utilizing the proper upkeep techniques, supplemented by regular assessment. When all these actions are taken, they should likewise be documented. The confirmation file consists of details such as the hazardous area classification drawing, makers' documents, tools certification, design drawings and calculations, evaluation documents, and documents of a person's competency and continuing professional development (CPD), such as via ECA's eCOMS software application.

Getting My Roar Solutions To Work

It is vital that pupils recognize and have a comprehensive understanding as to exactly what makes up a harmful location. The pupil needs to additionally recognize why training is necessary prior to attempting to tackle job or defining devices into a harmful area. These areas are also called classified locations and are specified as locations which have a high likelihood of an explosion because of the feasible existence of flammable gases, vapors, cleans and so on.

Industries that have unsafe locations are now demanding that electric employees that are specifying or working in these locations must have a harmful area qualification that regards them competent. Jobs in these sectors are extremely gratifying so you need to be prepared. To fulfill this need for the industry, across the country recognised training in Certification IV in Dangerous area Electric and EEHA training on the growth of competent professionals.

The Buzz on Roar Solutions

Technology Abilities Australia is a Registered Training Organization offering you with the most inexpensive and quickest way in obtaining your credentials - eeha training. Our trainers are industry certified and have a number of years of process experience. Our courses have actually assisted hundreds of individuals from company managers to everyday staff members in acquiring a solid hang on this not so difficult however high risk training

The training also consists of recognizing the unsafe areas, sources of surge and the buildings of unsafe materials along with the obligations and functions of all events, guidelines, systems, requirements and technique codes connected to harmful areas. We give instrumentation and harmful location services that are in compliance to most recent AS/NZS and international industry requirements.

Report this page